From the President

Dear Highport Marina members,

As promised, below are the details and specifics related to the replacement of our current, old and damaged breakwater system. We spent months in evaluation, investigation and engineering before deciding to contract Marine Development, Inc. (MDI) to design, engineer, fabricate and install our new wave attenuator (breakwater) system. MDI is one of the nation’s most respected and sought after marina development and construction companies. They have over 40 years of providing outstanding products and services to the marina industry and have built literally miles of wave attenuator systems across the United States.

MDI has completed detailed design drawings and engineering studies and have commenced fabrication of the more than 1,050 lineal feet of the new wave attenuator system. The fabrication process is anticipated to take 75-90 days to complete. When complete, the sections will be shipped to Highport Marina for installation on or near June 1st.

Installation of the new wave attenuator system will be a lengthy process due to the overall size and weight of each individual section, sections in totality, and the miles of galvanized cabling and expansive concrete anchoring systems that will need to be installed. The entire project is currently scheduled to be completed on or near August 1st with a total cost of +/- $1.5 million.

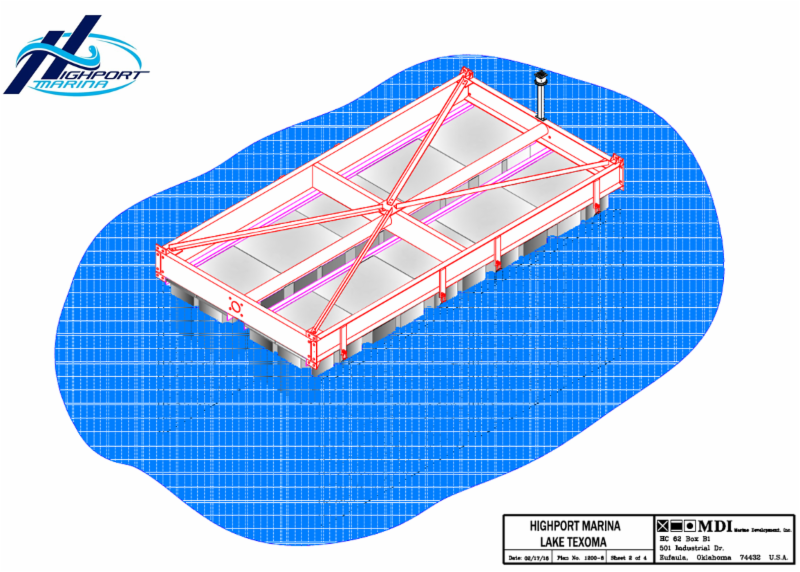

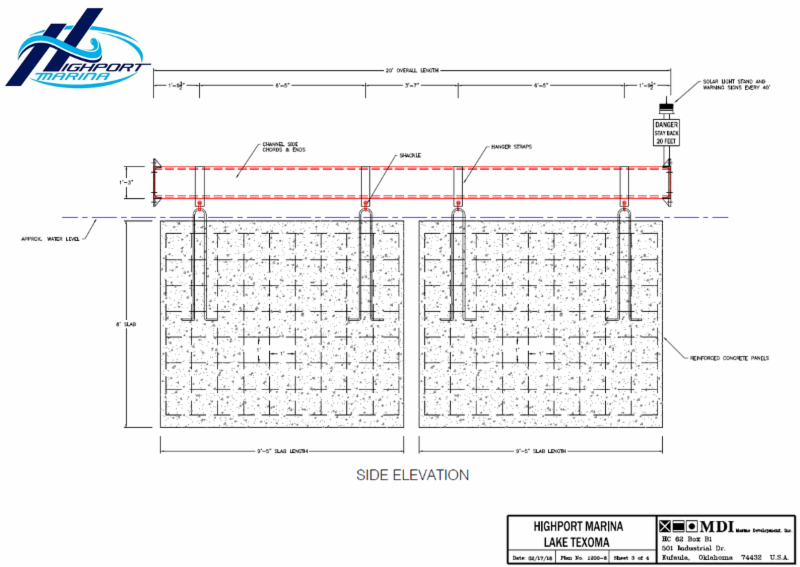

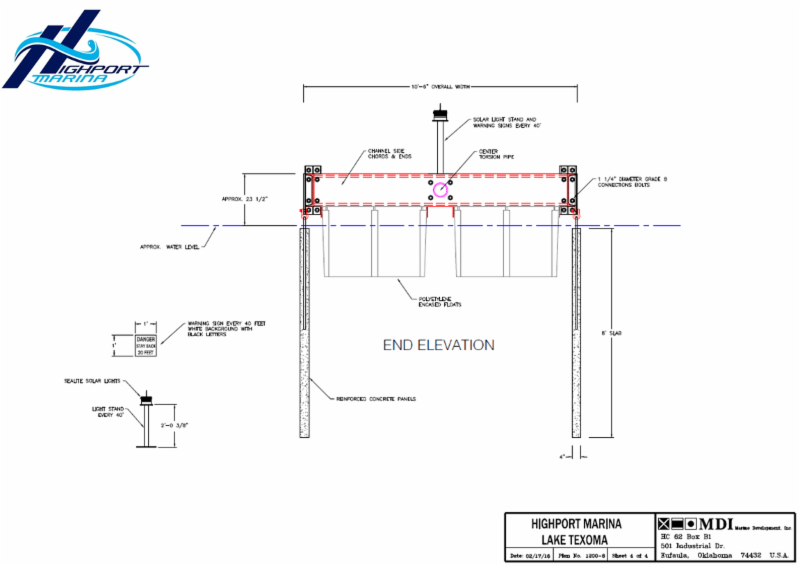

Below are illustrations provided by MDI in order to give you as much information as possible as it relates to this exciting new wave attenuator system.

Location – This illustrates the new alignment and location of new wave attenuator system. This alignment and location was carefully engineered to maximize wave attenuator system efficiency and minimize effects of the waves based upon our weather patterns, length of unprotected fetch, and predominantly damaging wind patterns.

Cabling and Anchoring System – This illustrates the magnitude of the miles of underwater galvanized cabling and concrete anchoring necessary to hold this wave attenuator system in place.

Top View of Attenuator System – This illustrates the galvanized I beam design with cross supports and encapsulated flotation system. This wave attenuator system is low profile in design so as to minimize visual impact but massive below water to minimize wave action. Every component of this system will be galvanized to maximize lifespan by minimizing effects of high salinity water of Texoma. The encapsulated flotation will be barely visible but will be major component of this low maintenance system.

Side Elevation of Attenuator System – This illustrates the size and mass of dual side-by-side concrete slab design. These massive precast concrete panels are the key to dissipating the strength of waves at water’s surface and up to 10′ below surface. This patented design feature is imperative to the overall ability of the system to literally destroy wave action.

End Elevation of Attenuator System – This illustrates the overall design concept by showing the massive precast concrete panels as they will hang from the galvanized twin I beam designed framing system. Thus, creating a double set (precast concrete panels) of wave attenuators that will increase the overall efficiency by doubling the wave breaking ability and strength.

The new wave attenuator system will be equipped with Aqua Signal LED illuminated signage, fixtures and bulbs for navigational and safety purposes in excess of current Marina Industry Standards.

I certainly hope that you can see from this information that we are committed to making a long term investment into the best wave attenuator system available for Highport Marina.

Thank you for your patience as we complete a project of this scale. We felt it was imperative to our goal for a better Highport Marina that we be extremely thorough in our search for the very best wave attenuator system with proper alignment and location for our specific location and conditions, due to the magnitude of the investment, the impact on our customers, and longevity of the finished product.

Respectfully,

Gerald “Dee” Greninger

President

Highport Marina